- #Best fusion 360 free tutorials absolutely free software#

- #Best fusion 360 free tutorials absolutely free series#

Explain and discuss how trends such as generative design and machine learning are influencing innovation, and how things are made.Summarize an understanding of digital manufacturing, principles of sustainable design, and manufacturing processes.By understanding how designs are both made and assembled, you'll learn to create better designs from the start.Īfter completing this course, you will be able to:

#Best fusion 360 free tutorials absolutely free series#

Through a series of lectures and hands-on exercises, this course provides the core philosophy behind the software.

#Best fusion 360 free tutorials absolutely free software#

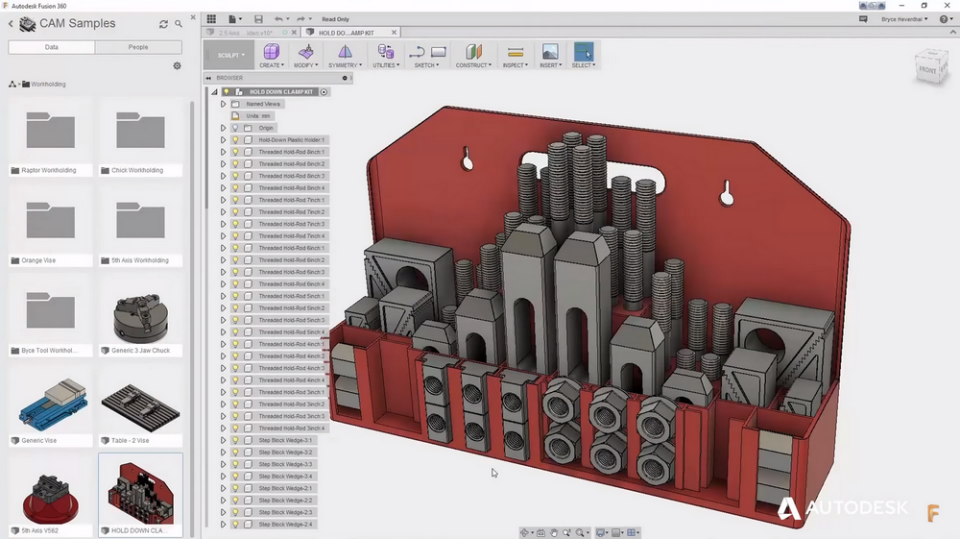

Fusion 360 is a cloud-based CAD/CAM tool for collaborative product development that combines industrial design, mechanical engineering, and machine tool programming into one software solution. This course will also explore foundational concepts behind Autodesk® Fusion 360™ CAD/CAM. This course introduces innovations in CAD and digital manufacturing, speaking to the rapid changes taking place that are forever transforming the future of making. Note that you can create holes by aligning with planes and points as well.The manufacturing industry is making a digital transformation, allowing companies to customize production through advances in machine learning, sustainable design, generative design, and collaboration, with integrated design and manufacturing processes. Usually you’d use this if you aren’t cutting a hole all the way through and object. While this is cooler, and is probably what you’d want for some outcomes, it will create a lot of extra geometry inside of Fusion 360, so use sparingly/only when you need.įinally, you also have the option to add a point to your hole that you’re drilling. One thing to point out about this is that it will give you an option for actually modeling the threads in 3D down below. The “tapped” option will actually add threads to your hole.

This will give you a list of different fastener types to choose from to dial in your fastener selection. If you’re designing for a certain kind of screw or bolt, you can actually cut holes designed specifically for certain kinds of screws and bolts by selecting the “clearance” hole tap type. You also have the option to recess your opening for a counterbore or a countersink type screw head. If you don’t want your hole to go all the way through, you can also set it so that the end of the hole comes to a point. A lot of the time, you’re probably going to just drag your hole depth, but type a value for the diameter. These can be changed either by clicking and dragging the arrows or by typing values. You can adjust many things about the hole you’re creating – the simplest being the size and diameter. Now let’s take a look at the options for actually creating your hole. If your sketch is like mine, you may have to click the “flip direction” button to get your hole to be cut in your object. For that one, it’s going to ask you to select sketch points from your 2D sketch as reference points. You also have the ability to reference an object in your model, like an edge, and set a distance from that object using the reference selection.īefore we go any further, let’s take a quick look at the multiple holes option as well. It will also inference to any points you have in your body – for example, for this box, it inferences to the natural center point.

Notice that you can drag the hole around to place it on any particular face. Whenever you click on the face, you’ll get this red preview of where the hole will be. So for example, in the case of this box, you’d select the top face. It’s going to ask you to set a plane from which you want to create your hole. Let’s take a look at the single hole placement option first. When you first activate the hole tool, you have two options – you can create a single hole, or you can select multiple holes based on different points in a sketch. However, if you use the built-in hole tool, you get access to a lot more different tools and functions than if you just cut a simple hole using an extruded circle. This is a totally valid way to cut holes and that’s not a bad thing. Now you could just draw a sketch circle then extrude it through an object and use the cut interaction. You’ll do this for a variety of reasons, including creating fasteners, openings, and more. One of the things you’ll be doing a lot of when working inside of Fusion 360 is cutting holes in objects. In today’s video, we’re going to discuss the hole tool – Fusion 360’s tool for cutting holes, adding threads, adding countersinks, and more!ĭo you like these Fusion 360 Tutorials? Make sure to subscribe to my YouTube channel to stay up to date on the newest videos! Subscribe Here – The Fusion Essentials YouTube Channel

0 kommentar(er)

0 kommentar(er)